NPXL vs Alternatives: Which Cognitive Boost Is Right for You?

September 28 2025FDA GMP: What It Means for Your Medications and Why It Matters

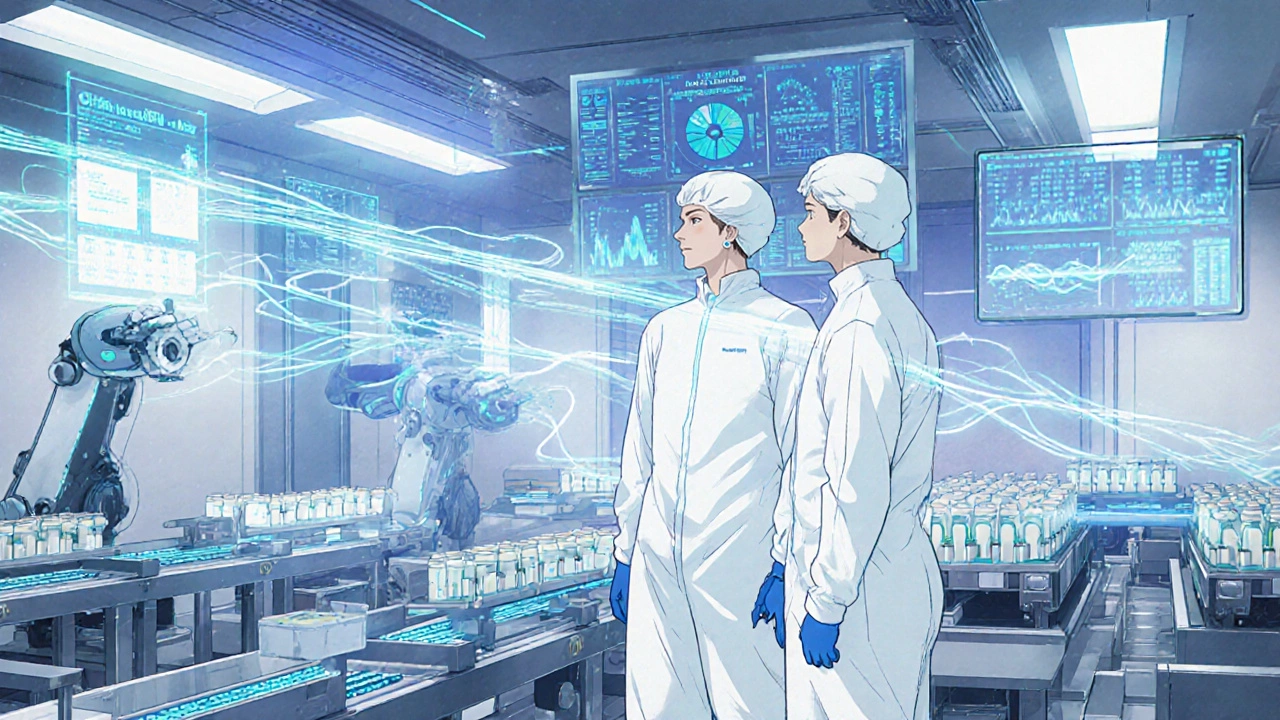

When you swallow a pill, you trust it will work the way it should. That trust isn’t luck—it’s built on FDA GMP, Good Manufacturing Practices enforced by the U.S. Food and Drug Administration to ensure drugs are consistently produced and controlled according to quality standards. Also known as cGMP (current Good Manufacturing Practices), it’s the invisible system that stops bad pills from reaching you. Without FDA GMP, your medicine could be too weak, too strong, contaminated with mold or metal, or even contain the wrong drug entirely.

FDA GMP isn’t just about clean rooms and lab coats—it’s a whole system that touches every step of making medicine. It covers everything from the raw ingredients to how pills are packaged and stored. For example, if a factory doesn’t control temperature and humidity during storage, your pills might break down before you even open the bottle. That’s why posts on medication storage and drug safety tie directly into GMP: if the maker doesn’t follow the rules, the end-user pays the price. The same goes for generic drugs. The FDA requires them to match brand-name drugs in strength, purity, and how they dissolve in your body. That’s not a suggestion—it’s a GMP requirement. When you see a generic pill, you’re relying on GMP to make sure it’s just as safe and effective.

It’s not just about big companies either. GMP applies to every facility that makes drugs, no matter how small. That’s why you’ll find posts about bioequivalence, dissolution profiles, and narrow therapeutic index drugs here. These aren’t just technical terms—they’re how GMP protects you from dangerous errors. For instance, a drug with a narrow therapeutic index, like warfarin or lithium, can kill you if the dose is even slightly off. GMP forces manufacturers to prove every batch is identical. If a lab skips a test or a worker doesn’t clean a machine properly, GMP audits catch it before the pills leave the plant.

And it’s not just the U.S. The FDA GMP standards are the global gold standard. Companies that export drugs to the U.S. must meet them—even if they’re in India, China, or Germany. That’s why your medicine, no matter where it’s made, carries the same safety promise. But GMP isn’t perfect. It’s reactive. It catches problems after they happen, not before. That’s why your pharmacist asks if you’ve noticed changes in how your pill looks or tastes. That’s your part of the system. You’re the final checkpoint.

Below, you’ll find real-world examples of how GMP shapes the medicines you use—from how generics are tested, to why your blood pressure pills must be taken at the right time, to how a cough syrup can become dangerous if misused. These aren’t random stories. They’re all connected to the same system: FDA GMP. It’s the reason your medicine works. And the reason you can trust it.

29 Nov

29 Nov

Current GMP Standards: Detailed Requirements Explained for 2025

Current GMP standards in 2025 require modern technology, digital data integrity, and strict supply chain controls. Learn the nine core requirements, key differences between FDA and EU rules, and how to stay compliant.

Read More...