Australia's Generic Market: PBS Overview and Impact

December 8 2025Pharmaceutical Manufacturing: How Drugs Are Made and Why It Matters

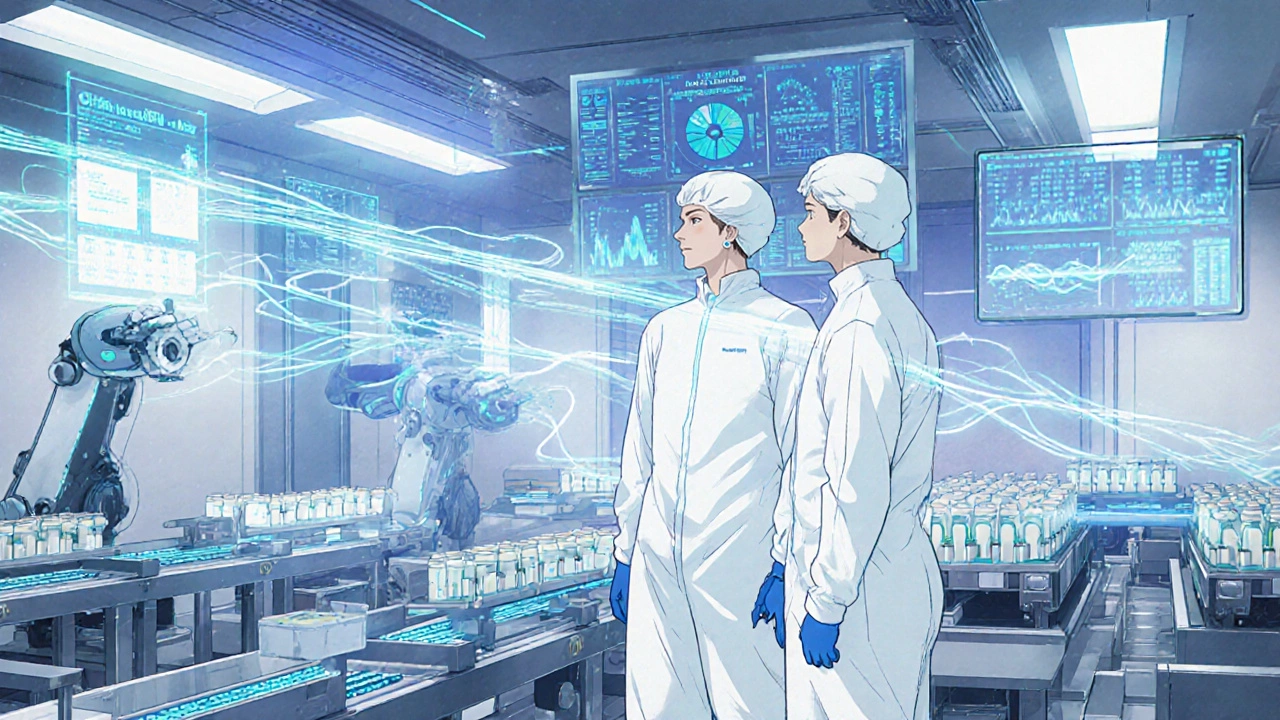

When you take a pill, you trust it will work the way it should. That trust comes from pharmaceutical manufacturing, the precise, regulated process of turning chemicals into safe, effective medicines. Also known as drug production, it’s not just mixing powders—it’s a science that controls every step to make sure your medication is pure, stable, and reliable. Behind every bottle of generic or brand-name drug is a factory where temperature, humidity, and timing are monitored down to the second. One wrong step can mean a drug loses potency, breaks down too fast, or even becomes harmful.

That’s why bioequivalence, the standard that proves generic drugs work just like brand-name versions is so critical. If a generic version doesn’t release its active ingredient the same way in your body, it could fail to treat your condition—or cause side effects. The FDA and other global agencies require strict testing, including dissolution profiles, how quickly a drug breaks down in lab conditions that mimic your digestive system. These tests don’t just check if the pill dissolves—they check if it dissolves at the right speed, every single time. That’s why two pills that look identical can still be very different if the manufacturing process wasn’t tightly controlled.

And it’s not just about the active ingredient. The fillers, coatings, and packaging all matter. A pill stored in a hot bathroom might degrade before you even take it. That’s why drug safety, the full system of controls from factory to pharmacy includes how drugs are packaged, labeled, and shipped. Even small changes in humidity during manufacturing can affect shelf life. That’s why posts here cover everything from how to store pills at home to why some drugs need special handling from the moment they leave the factory.

Some drugs, like those with a narrow therapeutic index, demand even tighter control. A tiny difference in how they’re made can mean the difference between treatment and toxicity. That’s why these drugs have stricter rules for generics, and why you’ll find detailed breakdowns here on how regulators ensure safety without slowing access to affordable medicine.

What you’ll find below isn’t just a list of articles—it’s a clear look at how the invisible work behind your medicine keeps you safe. From how dissolution tests prevent fake generics from reaching shelves, to why temperature control in warehouses matters just as much as in the lab, these posts connect the dots between factory floors and your medicine cabinet. You’ll learn what to ask your pharmacist, how to spot when a drug might be compromised, and why the same pill from two different makers might behave differently—even if the label says they’re identical.

29 Nov

29 Nov

Current GMP Standards: Detailed Requirements Explained for 2025

Current GMP standards in 2025 require modern technology, digital data integrity, and strict supply chain controls. Learn the nine core requirements, key differences between FDA and EU rules, and how to stay compliant.

Read More...