Atenolol and Tremors: What You Should Know

July 26 2023GMP Standards: What They Are and Why They Matter for Your Medications

When you pick up a prescription or buy an over-the-counter pill, you expect it to work—and you expect it to be safe. That’s not luck. It’s thanks to GMP standards, Good Manufacturing Practices that define how pharmaceuticals must be made, tested, and controlled to ensure quality and safety. Also known as cGMP, these rules are the backbone of every drug you use, from insulin to ibuprofen. Without them, you could be taking pills with the wrong dose, harmful contaminants, or even no active ingredient at all.

GMP standards aren’t optional—they’re enforced by agencies like the FDA, EMA, and Health Canada. These rules cover everything from the cleanliness of the factory floor to how workers handle raw ingredients, how equipment is calibrated, and how final products are tested. If a company skips a step—say, fails to control humidity during storage or doesn’t verify batch consistency—it’s breaking the law. And that’s not just a paperwork issue. Poor manufacturing can lead to failed treatments, dangerous side effects, or even death. That’s why the pharmaceutical manufacturing, the process of producing medicines under strict quality guidelines is one of the most tightly regulated industries in the world.

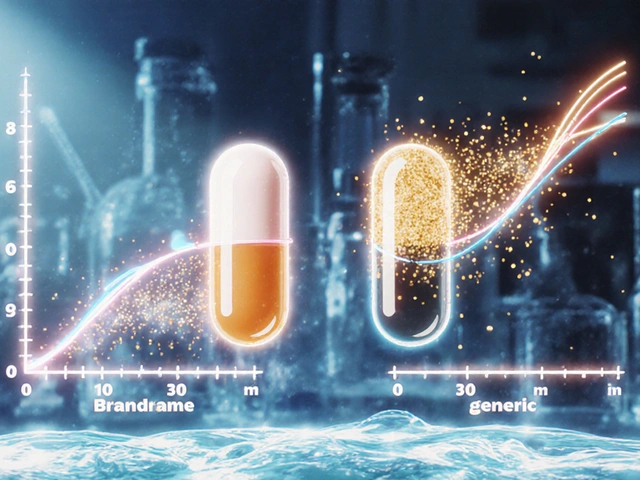

These standards directly connect to the topics you’ll find in the posts below. For example, drug safety, the protection of patients from harmful or ineffective medications isn’t just about what’s in the pill—it’s about how it was made. Temperature and humidity control during storage? That’s a GMP requirement. Why generic drugs must match brand-name dissolution profiles? That’s GMP in action. Even how labels are printed and verified ties back to GMP’s strict documentation rules. The FDA doesn’t just check if a drug works—it checks if every step of its journey from factory to shelf was done right.

Some people think GMP is just for big pharma. But it affects you every time you take medicine. If a batch of antibiotics is made in a dusty room without proper air filters, it could make you sicker. If a blood pressure pill isn’t mixed evenly, one pill might have double the dose of the next. That’s why GMP isn’t a bureaucratic hassle—it’s your insurance policy. The posts here dive into real-world examples: how dissolution profiles ensure generics are safe, why labeling rules can delay safety updates, and how narrow therapeutic index drugs demand even stricter controls. These aren’t abstract rules. They’re the reason your meds work when they’re supposed to—and don’t hurt you when they’re not.

What you’ll find below isn’t just a list of articles. It’s a map of how GMP standards touch every part of your medication experience—from the lab to your medicine cabinet. Whether you’re worried about expired pills, generic drug safety, or why your prescription tastes different, the answers start with GMP. These are the invisible rules that keep you safe. And now you know why they matter.

29 Nov

29 Nov

Current GMP Standards: Detailed Requirements Explained for 2025

Current GMP standards in 2025 require modern technology, digital data integrity, and strict supply chain controls. Learn the nine core requirements, key differences between FDA and EU rules, and how to stay compliant.

Read More...